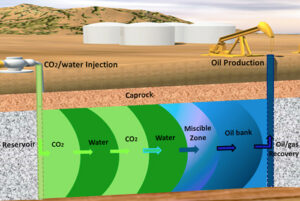

Water injection is a critical process in the oil and gas industry, used to maintain reservoir pressure and enhance oil recovery. This technique, also known as waterflooding, involves injecting water into the subsurface reservoir, often a porous sandstone or carbonate rock, to push additional oil to a production wellbore. The efficacy of water injection operations hinges on meticulous monitoring and management, ensuring optimal reservoir performance and environmental safety.

Understanding Water Injection

Before delving into the management and monitoring strategies, it is crucial to understand the basics of water injection. The primary goals are to increase oil recovery and maintain reservoir pressure. Over time, reservoirs naturally lose pressure, leading to decreased oil production. By injecting water, the pressure is maintained or increased, allowing for a more efficient extraction of the remaining oil.

Types of Water Injection Systems

- Continuous Injection: This system involves the constant injection of water into the reservoir.

- Intermittent Injection: Here, water injection is done in cycles, alternating with periods of no injection.

Monitoring Techniques

Effective monitoring is key to optimizing water injection operations. Several techniques are employed:

Real-time Data Acquisition

- Pressure and Temperature Sensors: These are installed in the reservoir and at various points in the injection system to monitor the conditions continuously.

- Flow Meters: These devices measure the rate at which water is injected into the reservoir.

Reservoir Simulation

- Advanced computer models simulate the reservoir’s response to water injection, predicting future performance and identifying potential issues.

Seismic Monitoring

- Seismic surveys help in understanding the changes in the reservoir due to water injection, particularly the movement of the oil-water contact.

Management Strategies

The management of water injection operations involves several key strategies:

Injection Water Quality Control

- Ensuring the injected water is of suitable quality is vital. Poor quality water can lead to scaling, souring (due to bacterial activity), or plugging of the reservoir pores.

- Water treatment facilities are often used to treat the water before injection.

Injection Rate and Pressure Management

- The rate and pressure of water injection must be carefully controlled to optimize oil recovery and avoid reservoir damage.

- Automated control systems are often employed for this purpose.

Zonal Isolation

- In heterogeneous reservoirs, it is important to isolate different zones to ensure efficient waterflooding.

- Techniques such as packers and selective injection are used for zonal isolation.

Challenges and Solutions

Scaling and Corrosion

- Regular monitoring and the use of scale inhibitors can mitigate these issues.

Water Breakthrough

- This occurs when injected water reaches the production wells, reducing oil quality.

- Monitoring production data and adjusting injection strategies can manage breakthroughs.

Environmental Considerations

- Minimizing the environmental impact is crucial. This includes managing the source of injection water and handling produced water.

Conclusion

Monitoring and managing water injection operations is a complex but essential aspect of enhanced oil recovery. Through effective techniques and strategies, operators can optimize oil production, extend the life of the reservoir, and minimize environmental impacts. Continuous innovation and adoption of new technologies will further refine these processes, ensuring sustainable and efficient oil recovery in the future.