In the world where black gold reigns supreme, water is its loyal companion. A seasoned journey through the oil-laden paths reveals the potency of water in unlocking the subterranean treasure troves. Water injection, a technique honed over decades, stands as a linchpin in the saga of oil recovery. This narrative unfolds the basics of water injection in oil recovery, a dance of molecules leading to the bounty of barrels.

The Rationale: Why Water Injection?

Oil fields are not perennial fountains; they tire with time. The pressure ebbs, and the flow of oil dwindles. Here’s where injecting water dons its cape. By injecting water, we rejuvenate the reservoirs, urging the reluctant oil to surface. It’s about maintaining the pressure, enhancing recovery, and ensuring the longevity of the oil field.

The Stages of Recovery

“The transition from primary to secondary recovery marks a shift from reliance on natural forces to an orchestrated effort in oil extraction”. And the art of injecting water is the maestro in this orchestration.

The Mechanism: How Does it Work?

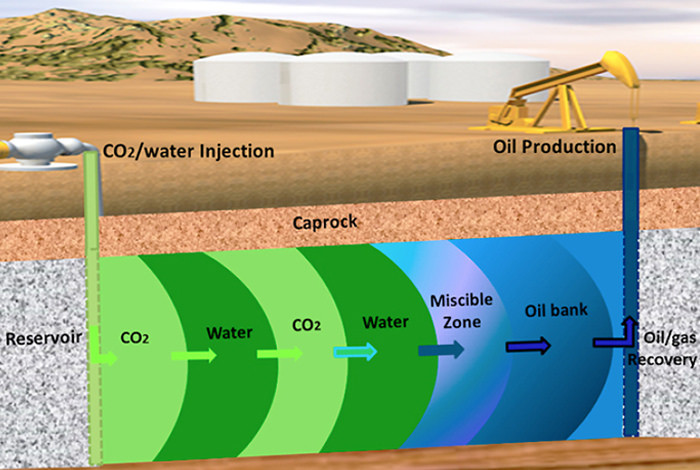

Water injection isn’t a mere inundation; it’s a calculated maneuver. It’s about the right pressure, the right volume, and the right placement. The injected water sweeps the oil, urging it towards the production wells. It’s an underground ballet, choreographed to the tunes of physics and geology.

The Choreography of Wells

The injection wells are the entry gates, while the production wells are the exit routes. Their placement, a play of geometry and geology, dictates the efficiency of injection.

The Variants: Customization is Key

Not all reservoirs are cast in the same mold, and hence the need for different flavors of injection:

- Continuous Water Injection: A ceaseless flow, maintaining a steady pressure.

- Intermittent Water Injection: A rhythmic pulse, a cyclical nudge to the reservoir.

- Selective Water Injection: A targeted approach, focusing on specific zones within the reservoir.

Each variant, a tailored suit fitting the contours of the reservoir, ensuring the optimum extraction.

The Technical Embroidery: Precision and Purity

Water injection is a tapestry of engineering precision and fluid purity. The quality of water, devoid of impurities, is crucial to prevent clogging or reservoir damage. Likewise, the engineering of injection systems, a melody of pressure maintenance and flow control, is pivotal in ensuring the efficacy of the system.

Navigating Challenges: It’s Not Always Smooth Sailing

Water injection, though a boon, comes with its share of challenges. The treatment of water, the assessment of reservoir conditions, and the design of injection systems demand a blend of expertise and experience. Yet, the rewards are bountiful, a gush of oil heralding the success of injection.

Water injection is not a chapter in the annals of oil recovery; it’s a volume. It’s a testimony to the ingenuity in harnessing the simple, yet potent, essence of water. A dive into the basics of injection is a dive into the heart of oil recovery, a journey rich in learning and laden with liquid gold.

Visit these links to learn more: